Add to Cart

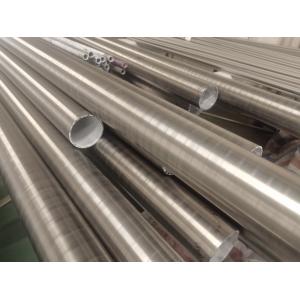

Zirconium Seamless Tube 100% Eddy Current Ultrasonic Hydrostatic Test Include

| Zirconium Tube Basic Information | |

| Standard

| ASTM B523/B523M-2012a |

| Material Brand

| R60702, R60704(Tin Alloy) |

| Size Range

| OD 10-219mm; WT 0.5-22mm; Length≤16000mm. |

| Inspection

| Eddy Current Test; Ultrasonic Test; Hydrostatic Test; Size Test. |

| Purpose

| Traditional petroleum, chemical equipment, and medical fields etc. |

Introduce:

Zirconium tube is an alloy tube shaped material made from metal zirconium and other metals. Due to the excellent nuclear and corrosion resistance properties of zirconium, zirconium alloy tubes are often used as important nuclear materials for nuclear fuel components and internal structures in water-cooled reactors. Pure zirconium tubes are mainly used for manufacturing chemical equipment, as they are expensive and require only a small amount of material. The chemical composition and usage of commonly used zirconium tubes are shown in the table, among which zirconium tin alloy tubes are used in a large amount.

Process characteristics

1. Zirconium has a strong affinity for gases. It reacts with oxygen, hydrogen, and nitrogen at approximately 200, 300, and 400 ℃, respectively. At higher temperatures, the reaction is rapid, so melting and heat treatment must be carried out in a vacuum furnace. When Hot working is carried out in the atmosphere, proper protective measures shall be taken and the operation time under high temperature shall be shortened.

2. The friction coefficient between zirconium and the mold is relatively high, making it easy to adhere to the surface of the mold; The thermal effect of plastic deformation is significant, and good lubrication conditions are required during processing.

3. Processing specifications have a sensitive impact on the usability of products. Special attention should be paid to controlling the cold processing and heat treatment processes before the finished product to meet usage requirements.

4. The dimensional accuracy and surface quality requirements of pipes are very high. Therefore, the process equipment should have good accuracy, and the design and production of molds should be advanced and reasonable.

Advantages:

Zirconium is a rare metal with astonishing corrosion resistance, extremely high melting point, ultra-high hardness and strength, and other characteristics

|

Chemical Requirements

| ||

|

Element | Composition, % | |

| UNS Grade Designation R60702 R60704 | ||

| Zirconium+hafnium, min | 99.2 | 97.5 |

| Hafnium, max | 4.5 | 4.5 |

| Iron+chromium | 0.2 max | 0.2-0.4 |

| Tin | / | 1.0-2.0 |

| Hydrogen, max | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 |

| Niobium | / | / |

| Oxygen, max | 0.16 | 0.18 |